Product code

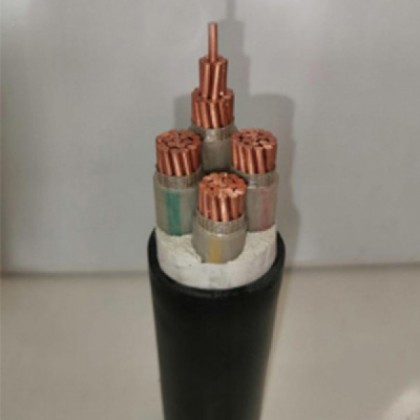

1. Conductor code

Insulation YJ: Crosslinked polyethylene (XLPE) insulation

Sheath Y: Polyethylene or polyolefin sheath

Armor code

2: Double steel strip armor 3: Fine round steel wire armor

4: Coarse round steel wire armor 6: Non magnetic metal tape armor

7: Non magnetic metal wire armor

Outer sheath code

Sheath 3: Polyethylene or polyolefin sheath

Product Usage and Introduction:

This series of products is suitable for energy distribution in power frequency rated voltage 0.6/1kV transmission and distribution systems.

Low smoke and halogen-free wires and cables produce a very small amount of smoke under flame combustion, and the released gas does not contain halogen (low halogen) elements and is non-toxic (low toxicity). When a fire occurs, it can greatly reduce the harm to instruments, equipment, and human health, and is therefore widely used in high-rise buildings, hospitals, large libraries, disaster prevention command and dispatch buildings in sports venues, stations and civil airports, passenger waiting rooms, key cultural relics protection sites, as well as underground high-speed trains, underground shopping malls, or densely populated public places. The plastic insulated wires and cables with a rated voltage of 35KV and below developed and produced by our company not only meet the requirements of GB/T12706.1-2020 and GB/T5023-2008, but also have formed a series of flame retardant and fire-resistant types, especially low smoke and halogen-free (low halogen) performance that meets the national standard GB/T19666-2005. After national level scientific research, this type of product has reached the advanced level of similar products in China.

Some characteristics of low smoke halogen-free cables:

1. Halogen free: Low smoke halogen-free cables use insulation layers, sheaths, and specially designed oxygen barrier materials that are different from ordinary wires and cables, ensuring that the product is halogen-free, Avoiding the secondary pollution caused by the burning of wires and cables during fires effectively increases the chances of successful evacuation in extreme situations.

2. Low smoke: In addition to being halogen-free during burning, we can also see from the naming that low smoke halogen-free cables have a "low smoke" characteristic, which is that the smoke produced by this type of wire and cable during combustion will be very low concentration (compared to ordinary wires and cables) - the light transmittance is generally greater than 40%, which is much higher than the light transmittance of ordinary wires and cables, which is less than 20%, which is conducive to the evacuation of personnel in case of fire and the subsequent firefighting and disaster relief work.

3. Low toxicity and no production of corrosive gases, in essence, the third point can be considered as a supplement to the first two points of "low smoke" and "halogen-free" characteristics. Low smoke and halogen-free cables use toxic heavy metals such as lead and cadmium as insulation and sheath for wires and cables, which will not cause pollution to soil and water sources during the use and disposal of wires and cables; At the same time, its materials do not contain elements such as halogens that can cause corrosive reactions during combustion, emit minimal acidity, and have a low smoke emission rate, making it very friendly to personnel, equipment, and the environment.

Because of these advantages and characteristics of low smoke and halogen-free cables, in many key projects with high safety requirements, such as schools, supermarkets, hospitals, office buildings, etc., low smoke and halogen-free cables are preferred when purchasing wires and cables to ensure the safety and stability of power transmission.

You are here:

You are here: